Ideal for Wheel Service

The Tekton flip socket is both longer and has lower stepped shoulders than competitors to give you maximum reach into lug nut wells.

The outer diameter is 1 to 2 mm smaller than other Tekton impact sockets, allowing for better access in tight lug nut wells.

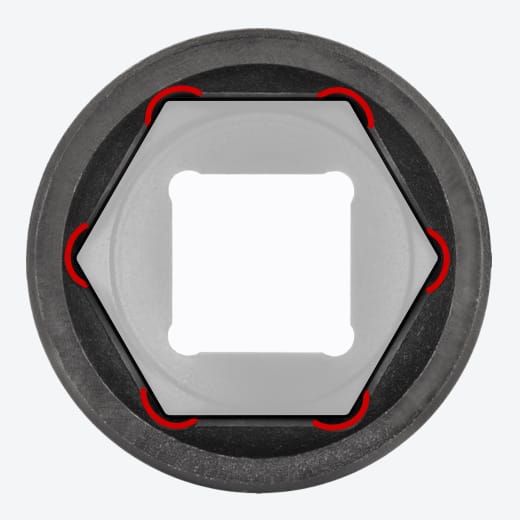

The radiused corners prevent fastener round-off by applying force to the flat sides of a lug nut, rather than its corners.

The steep 60° chamfered opening makes it easy for the flip socket to slide over lug nuts.

Each socket well is extra deep to provide increased engagement with lug nuts and clearance for decorative caps.

The size is marked in two ways on every socket—both as a high-visibility laser marking and a permanent stamped marking.

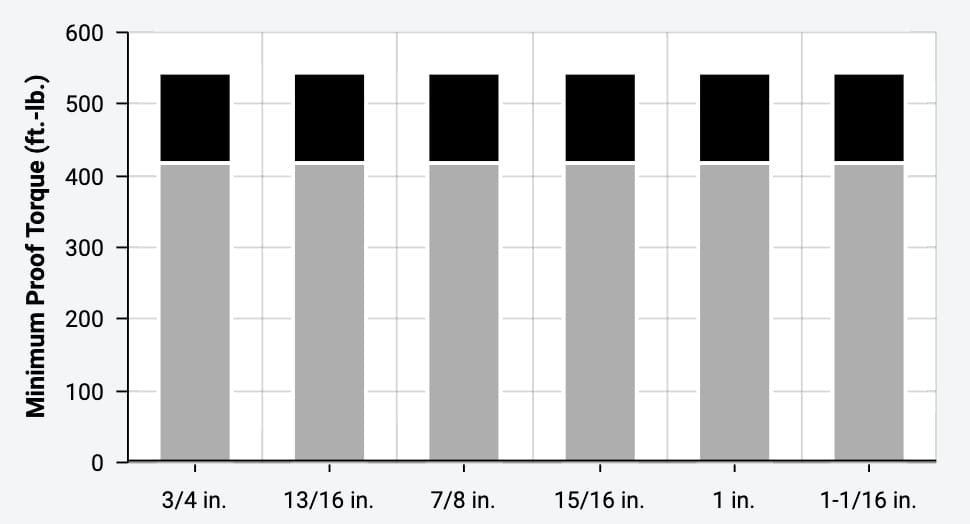

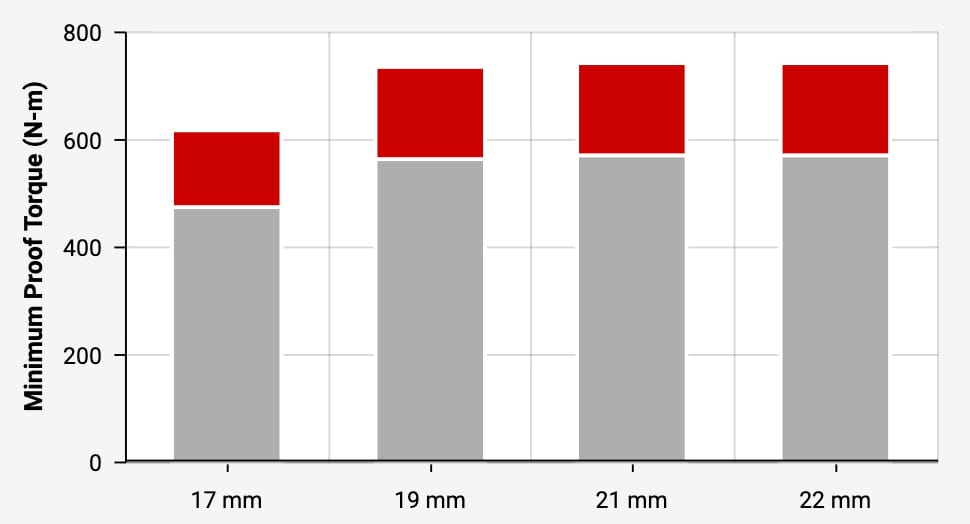

Each flip socket size meets a minimum of 1.3 times the ANSI/ASME standard for proof torque.

(A single-cycle test applies torque until a specified value is reached without failure or permanent deformation.)

INCH SERIES

| ANSI | TEKTON | ||

| Source: ASME B107.110-2012 | |||

METRIC SERIES

| ANSI | TEKTON | ||

| Source: ASME B107.110-2012 | |||

The flip sockets are made from 4140 Chromium-Molybdenum steel

All pieces have a corrosion-resistant manganese phosphate coating.